As we all know, Formula 1 is one of the most technologically advanced motorsports in the world. Since it was started in 1950, it has gotten major advancements, especially with the cars because they got evolutionary upgrades like monocoque chassis, different buttons on the steering wheel, DRS or Drag Reduction System for even less drag on the straights, Halo and so on. Some of these technologies in F1 cars might sound familiar to you because, over the years car manufacturers across the globe have adapted some of these F1 inventions into their road cars, and here are 5 of them discussed below.

Monocoque Chassis

A monocoque chassis is a combined tubular structure generally made of aluminium of a car body and chassis because, it is lightweight and makes it easy to place body panels, engine and transmission, and helps in better handling. At first, the aluminium monocoque chassis was used in a Formula 1 Car in 1962 by the team Lotus for their 25. But later, in 1981 aluminium monocoque chassis in Formula 1 was replaced by carbon fibre monocoque chassis, first used in the McLaren for their MP4/1. The first road car was the 1990 Jaguar XJR-15, which was built on a monocoque structure made out of carbon fibre, and today, from Maruti Suzuki to Bugatti, every manufacturer produces cars built on monocoque chassis.

Steering Mounted Controls

Steering-mounted controls in road cars help the driver to function in almost everything from cruise control to controlling the AC vents without keeping the eye off the road. For the first time, the buttons on the steering wheel were invented for the F1 cars back in the 1970s, which at first included the engine kill switches & the pit radio button, but later on, the steering wheel got more advanced, with different knobs, switches, buttons for neutral and park and so on. The first car to be equipped with steering-mounted controls was the 1984 Nissan 300ZX Turbo 50th Anniversary Edition.

Paddle Shifters

The Paddle shift gearbox helps the driver to shift gears manually in an automatic car with the paddles placed behind the steering wheel, which also increases the driving engagement between the car and the driver. In the 1980s, F1 drivers had a traditional knob lever to shift gears, but in 1989 for the first time paddle shift gearbox paired with a semi-automatic transmission was invented by Ferrari for their 460 F1 car, which eased out the gear-changing for F1 drivers and made racing more engaging. The first car to get paddles behind the steering wheel to shift gears was the 1995 F355 F1 Berniletta.

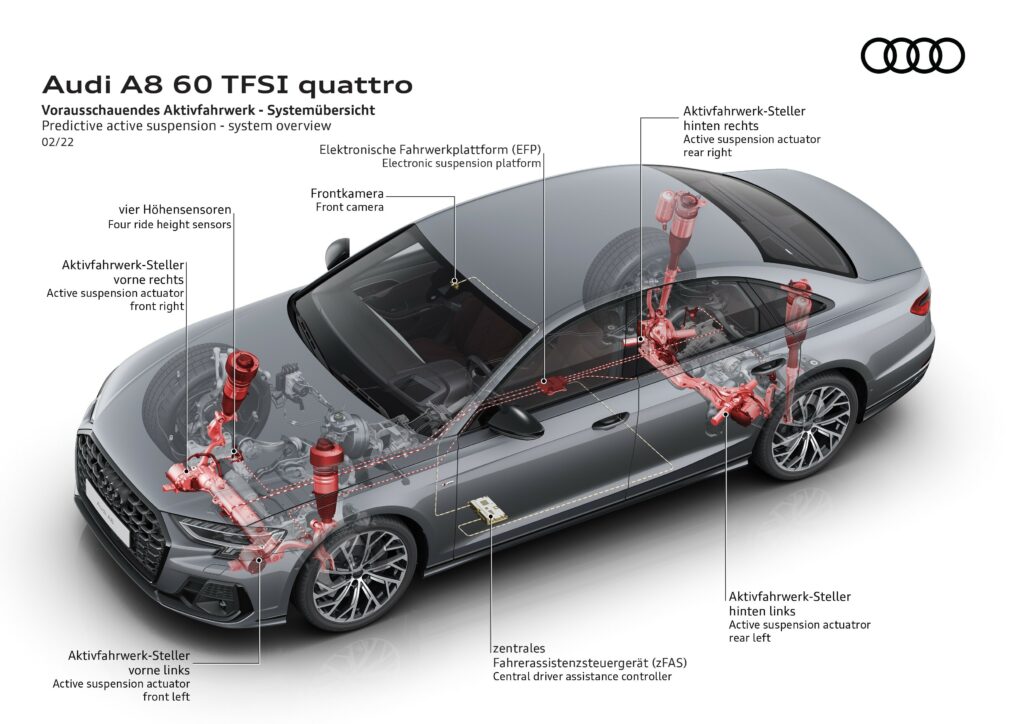

Adaptive/Active Suspension

The Adaptive or active suspension technology helps luxury cars or cars, in general, to soak bumps and provide soft ride quality and makes the car handle properly in sharp corners at high speeds. Well, it had already come in cars like the 1983 Toyota Soarer but, the Williams F1 team took this technology to the next level in 1992 with their FW14B, which helped it handle high-speed corners more efficiently with more grip and less effort, which made it one of the most dominant cars in F1 history and faster than any other car on the grid at that time. Later, many supercars like the Lamborghini Aventador SVJ and many luxury cars like the Land Rover Range Rover have adapted this technology.

DRS: Drag Reduction System

DRS or Drag Reduction System is the technology only for road-legal performance cars for the track. This system includes a flap on the rear wing of the car connected via a button on the steering wheel which says DRS, by pressing that button the flap opens and provides more downforce to the car on the straights on a race track. The Drag Reduction System was introduced in F1 in 2013, which made overtaking easier on the straights and made racing even more engaging for the driver as well as for the viewers and in the same year, the DRS technology was used by McLaren in their P1 hypercar to reduce drag its on high speeds and to help it in braking as well. And then after almost a decade after the P1 came out, Porsche introduced their 992 911 GT3RS with the DRS, which produces 850kg of downforce while the DRS applied, which is the most highest amount of downforce produced by a production car to date.